The Fourth Industrial Revolution has begun.

What’s Industrial Automation?

When Industrial revolution began in 1760, it transformed the world, shifting the focus from skilled man-power to special-purpose machinery. We could now manufacture goods more quickly, reliably and cost-efficiently. It paved way for thousands of new industries that leveraged the power of machines to produce goods at scale.

While machines became good at eliminating repetitive jobs, industries still needed highly-qualified professionals, who could control, monitor and maintain the complicated manufacturing workflows. Industrial automation aims at bringing complete autonomy to the manufacturing sector, allowing businesses to take decisions based on data, rather than intuition.

Using M2M (machine-to-machine) communication and network of intelligent sensors, industries can now create fully-automated processes that can take contextual decisions, with minimal human intervention. It’s estimated that industrial automation would massively reduce the operational costs of businesses, while improving the cumulative throughput and turnaround time.

Improve Productivity. Reduce Costs. Enhance Predictability.

As every business looks to improve its capacity and reach, operational hassles create a major frictional overhead for exponential growth. Industrial automation eliminates unpredictability by collecting data from intelligent sensing systems, thereby providing complete transparency into production count, total spillage and turn-around time.

Apart from improving predictability, automating your production workflow also eliminates the need for active monitoring, as our intelligent IoT system tracks all the critical parameters in the background, and automatically takes corrective action. The sweet combination of lower operational costs and higher predictability results in improved bottom-line margins for businesses.

Track machinery movements.

Our retrofit sensors plug into existing legacy systems, giving you the flexibility to adapt quickly and scale swiftly. From monitoring the temperature of boilers to tracking machinery movements. we offer wide-spread applications.

Automate processes. Streamline workflow.

Once you have connected the basic industrial units, you can now create a lego-block setup that facilitates autonomous M2M (machine-to-machine) communication. Using the building-block framework, you can now completely automate a process or workflow, depending upon the level of complexity.

Monitor production line in real-time. (IoT)

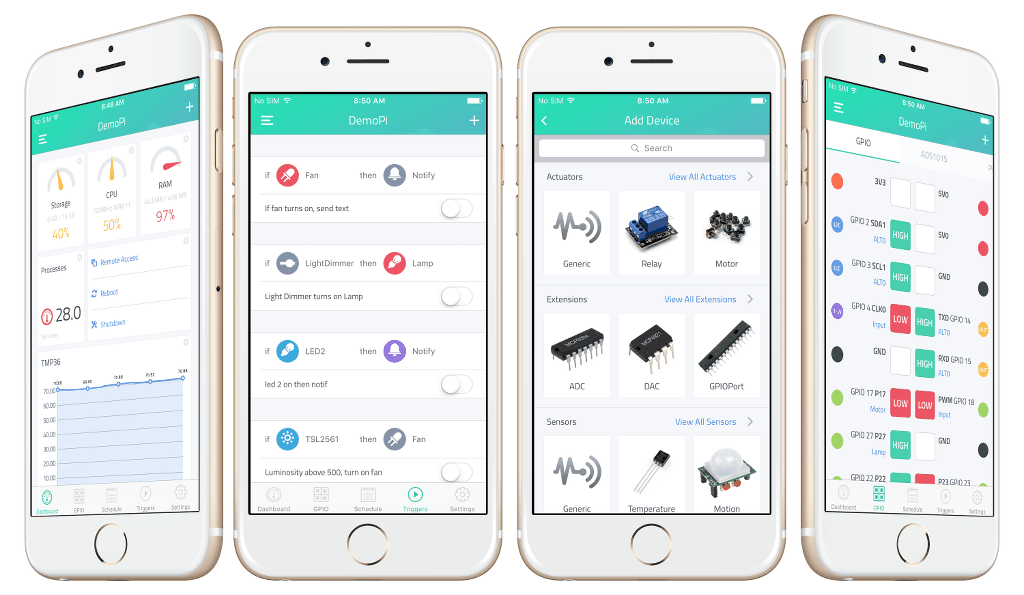

Do you wish to get automatic real-time updates of what’s happening in your factory/plant? Our IoT framework helps you connect your business to cloud, so that you can monitor the operational parameters of your business from your smartphone, tablet or computer device.

Get alerts and notifications.

Using industrial automation, you can create an interplay between all functional elements of your business. Want to be notified when the production stops, or get instant alerts when the output is low? Industrial automation monitors your workflows in the background, so that you can take care of what matters the most.

Track your inventory with GPS monitoring.

Tired of drivers not picking up calls? Do you wish you could track all your vehicles in real-time, so that you can provide accurate, in-time status updates to stakeholders? We’ve got your back. Our technology partners provide you the flexibility to track vehicles in real-time, from anywhere in the world.

Visualize your data. Get better insights.

Monitor your production workflow in real-time. Know how much energy, time or resources your machines consume. Use the collected data to improve productivity, reduce leakages and optimize industrial processes.